The global beverage industry is currently navigating a period of unprecedented transformation, driven by shifting consumer preferences, a heightened focus on sustainability, and the relentless pursuit of operational excellence. In Ireland, a nation with a rich heritage in beverage production ranging from artisanal spirits to global soft drink brands, manufacturers are increasingly turning to advanced automation to maintain a competitive edge. A prominent Irish beverage producer recently marked a significant milestone in this journey by integrating a state-of-the-art vertical transport solution into its facility, effectively bridging the gap between production floors and mezzanine-level processing units. This strategic upgrade, centered on the Qimarox Prorunner mk5, serves as a masterclass in how localized engineering expertise and global technological innovation can converge to solve complex logistical bottlenecks.

The catalyst for this modernization was a familiar challenge in the manufacturing sector: the "ceiling" of physical capacity. As consumer demand for the company’s products surged, the existing production infrastructure began to strain under the weight of increased throughput requirements. Specifically, the movement of secondary packaging—primarily cardboard boxes and cases—from the primary production floor to elevated processing and palletizing areas had become a critical point of failure. Historically, this vertical movement relied heavily on a combination of manual labor and the intensive use of forklifts. While functional for lower volumes, this approach proved increasingly untenable as scales tipped upward. Forklift operations, while versatile, introduce inherent risks to workplace safety, require significant floor space for maneuvering, and are subject to the variability of human operators. Furthermore, manual handling of heavy cases at height presents ergonomic risks and slows the overall cadence of the production line.

Recognizing that the traditional "horizontal" mindset was no longer sufficient, the manufacturer sought a solution that could leverage vertical space without sacrificing speed or safety. The objective was clear: implement a robust, automated vertical transport system that could integrate seamlessly with existing conveyor networks while adhering to the uncompromising hygiene and safety standards of the food and beverage industry. To achieve this, the manufacturer collaborated with Noreside Engineering, a distinguished system integrator based in Kilkenny. Noreside brought to the table a wealth of experience in process automation across both the pharmaceutical and food sectors—industries where precision and compliance are paramount. The partnership paired Noreside’s deep understanding of the local Irish manufacturing landscape and project management prowess with the globally recognized vertical transport technology of Qimarox.

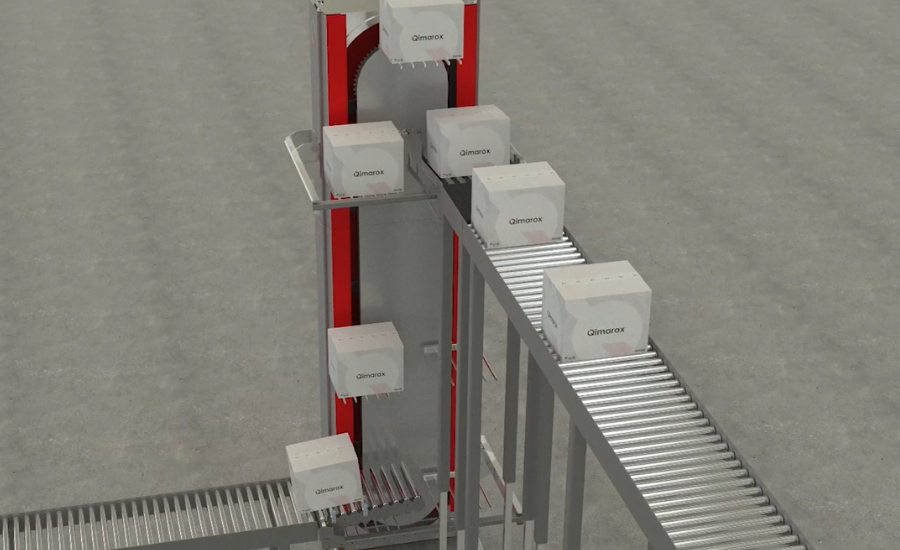

At the heart of the newly installed system is the Qimarox Prorunner mk5, a continuous vertical conveyor that has redefined expectations for high-capacity material handling. Unlike traditional reciprocating lifts, which operate on a "start-stop" cycle similar to an elevator, the Prorunner mk5 utilizes a patented continuous motion design. This allows products to be fed into the lift and transported upward in a fluid, uninterrupted stream. For a beverage manufacturer dealing with high-speed packaging lines, this continuity is essential. It eliminates the "accordion effect" where products bunch up while waiting for a lift carriage to return to the ground level, thereby ensuring a steady flow of goods to the next stage of the supply chain.

The technical specifications of the Prorunner mk5 are particularly suited to the rigors of beverage production. One of its most compelling features is its compact footprint. In an era where industrial real estate is at a premium, the ability to transport goods vertically within a minimal area allows manufacturers to reclaim valuable floor space for additional production machinery or storage. Furthermore, the system is engineered for low energy consumption. By utilizing gravity and a sophisticated drive system, the mk5 requires significantly less power than traditional hydraulic or heavy-duty mechanical lifts, contributing directly to the manufacturer’s sustainability goals and reducing long-term operational costs.

Hygiene and durability were also non-negotiable factors in this installation. The beverage industry is subject to strict regulatory oversight, and any equipment integrated into the production environment must facilitate easy cleaning and prevent contamination. To meet these demands, the entire conveyor system provided by Noreside Engineering, including the Prorunner mk5, was constructed from high-grade stainless steel. This choice of material ensures resistance to corrosion from potential liquid spills and allows for rigorous wash-down procedures. The system was designed in strict accordance with Good Manufacturing Practice (GMP) and the guidelines set forth by the European Hygienic Engineering & Design Group (EHEDG). These certifications provide the manufacturer with the assurance that their vertical transport solution not only enhances efficiency but also upholds the highest standards of food safety.

The integration process itself required meticulous planning. Noreside Engineering designed a bespoke stainless steel conveyor system that feeds the Prorunner mk5, ensuring a smooth transition of cardboard boxes from the packaging machines. The modular nature of the Qimarox technology played a vital role here. Because the Prorunner mk5 is built on a modular platform, it could be tailored to the specific height requirements of the Irish factory and easily integrated with the surrounding infrastructure. This modularity also offers a degree of "future-proofing." Should the manufacturer need to increase capacity further or reconfigure the production layout in the coming years, the system can be adapted or expanded with minimal disruption, protecting the initial capital investment.

Since the system went live, the improvements in the Irish facility have been both measurable and profound. The most immediate impact was the elimination of the forklift bottleneck. By automating the vertical flow of goods, the manufacturer has significantly reduced the number of forklift movements required in the packaging area. This has created a much safer working environment for employees, reducing the risk of collisions and traffic-related accidents. From an efficiency standpoint, the "smooth flow" achieved by the continuous conveyor has removed the delays that previously plagued the transition between the production floor and the palletizing level. The throughput of beverage packaging is now consistent and predictable, allowing the downstream palletizing robots and distribution teams to operate at peak performance.

The success of this project also highlights the importance of the "Total Cost of Ownership" (TCO) model in modern manufacturing. While the initial investment in an automated system like the Prorunner mk5 is higher than maintaining a manual, forklift-based process, the long-term savings are substantial. Reduced labor costs, lower energy bills, minimal maintenance requirements, and the avoidance of safety-related incidents all contribute to a rapid return on investment. Furthermore, the increased reliability of the system means fewer unplanned outages, ensuring that the manufacturer can meet its delivery commitments to retailers and distributors with unwavering consistency.

Looking toward the future, this installation serves as a blueprint for other manufacturers in the region. As the industry moves toward "Industry 4.0" and the "Smart Factory" concept, the ability to interconnect different levels of a facility through intelligent, automated transport systems becomes a necessity rather than a luxury. The data-ready nature of modern conveyors allows for integration into broader Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) platforms, providing real-time visibility into the movement of every box and pallet.

In conclusion, the collaboration between the Irish beverage manufacturer, Noreside Engineering, and Qimarox has resulted in a world-class logistics solution that addresses the core challenges of modern production. By elevating their thinking—quite literally—the company has overcome the constraints of their physical space, enhanced the safety of their workforce, and optimized their supply chain for the demands of a global market. The Prorunner mk5 stands as a testament to the power of specialized engineering, proving that even the most traditional industries can reach new heights through the strategic application of vertical automation. As this leading manufacturer continues to grow, its investment in high-capacity, hygienic, and efficient vertical transport will remain a cornerstone of its operational success, ensuring that every bottle and carton reaches its destination through a process that is as seamless as it is sophisticated.